Image

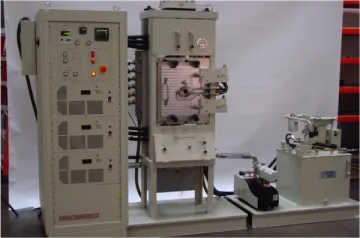

Spark Plasma Sintering (SPS) furnace is used to rapidly consolidate parts using a SPS 10-3 furnace from Thermal Technology (Santa Rosa, CA). SPS applies a pulsed direct current through a conductive graphite die assembly while simultaneously applying pressure. The die is heated through joule heating and conduction. By ultilizing joule heating, rapid heating rates (<600°C/min) can be obtained reaching temperatures >1500°C in minutes. SPS 10-3 capabilities are listed below.

| Maximum Current | 3,000 amps |

|

Maximum Load |

10 tons |

| Environment | Vacuum or Inert |

| Maximum Stroke | 10 inches |

| Chamber Size | 12" x 11" x 18" |

| Ram Size | 2.5 inches |